× CLOSE

ELECTRONICS DEPARTMENT

Electronics Department

Exhaustive quality control

and the concentration of advanced technologies

Craftsmanship based on the concentration of advanced

technology with a steady eye developed through long experience

Flat Electronics is constantly improving its products to provide the highest possible quality, in order to support and advance today’s technology.

Process

Manufacturing Processes

01Sputtering

Sputtering forms resistors and electrodes with high adhesion.

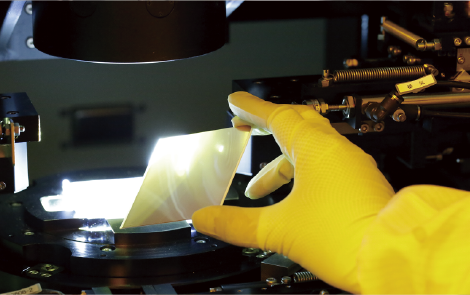

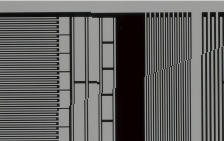

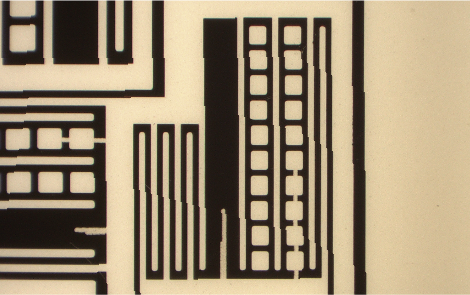

02Photo lithography

Photo lithography forms resistance patterns with line widths of 10μ or less.

03Annealing

Annealing stabilizes resistive films, to achieve temperature coefficient of 1ppm/°C.

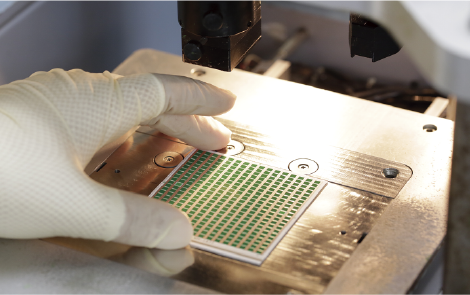

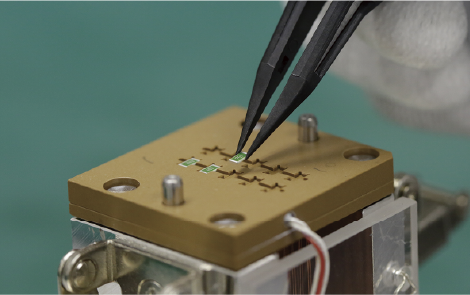

04Laser trimming

Laser trimming uses a laser to cut resistance patterns, to achieve resistance value precision of 0.01%.

05Screen printing

Screen printing prints an epoxy-type protective layer to maintain the moisture resistance of resistors.

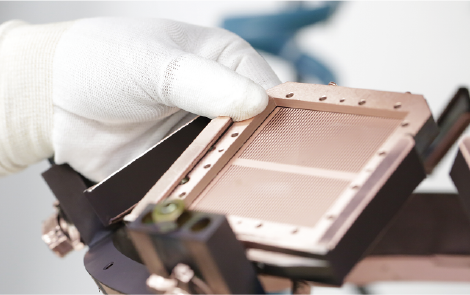

06Vapor deposition

Vapor deposition forms side-face electrodes on chip components.

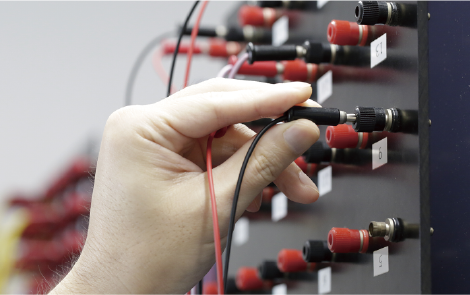

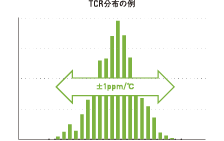

07TCR inspection

TCR inspection precisely measures the temperature properties of resistances.

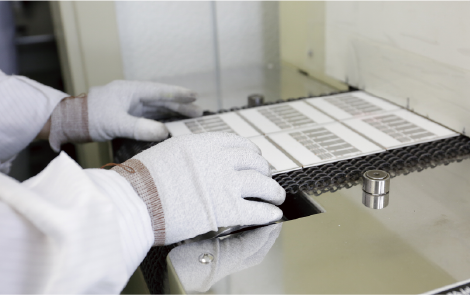

08Inspection taping

This process automatically inspects resistance values and appearance, and packages components.

09Reliability testing

Test conditions vary temperature, humidity, atmospheric pressure, and input power, to ensure the reliability of resistances in the market.